Our Approach

2025

Polyplastics Launches New Eco-Friendly PLASTRONⓇ ︎LFT with Reduced Weight, Higher Rigidity, and Strong Damping

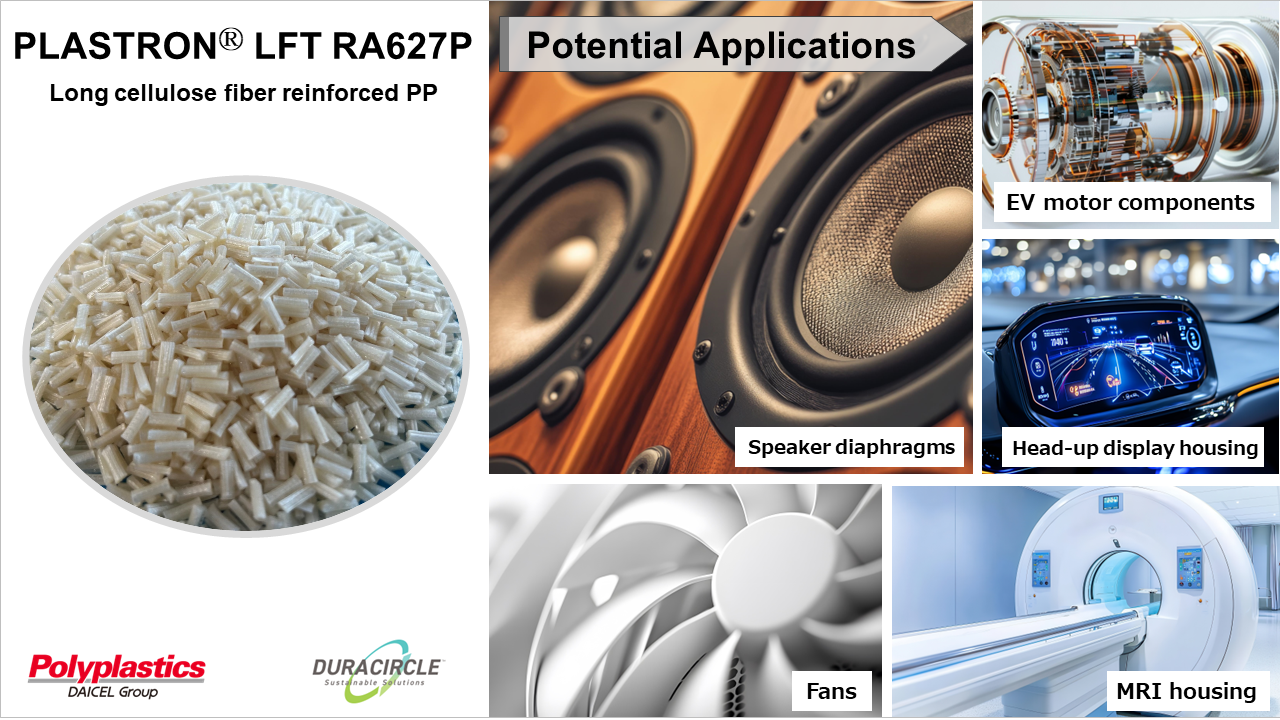

In January 2025, we released PLASTRONⓇ LFT (Long Fiber Reinforced Thermoplastics) RA627P long cellulose fiber reinforced polypropylene (PP) resin. PLASTRONⓇ LFT RA627P is a new grade that is a composite of PP resin and cellulose fiber which is a biomass material. Its main properties are low density and high specific rigidity*1, though it is also notable for having excellent damping properties due to its large loss coefficient. These properties make it well suited for use in audio components such as speaker diaphragms and for uses such as housings of industrial components that require strong damping. Using PLASTRONⓇ LFT RA627P results in products that are lighter in weight and at the same time eco-friendly, and also makes it possible to design products with excellent damping properties.

*1 Specific rigidity: The resulting value when tensile modulus is divided by density

Background behind the development of PLASTRONⓇ LFT RA627P

PLASTRONⓇ LFT is a resin composite of uninterrupted reinforcing fibers of the same length and oriented in the same direction inside of pellets. It is a material that offers both high rigidity and high impact strength. Glass and carbon fiber have conventionally been used as reinforcing materials. However, through our commitment to offering the market materials with lower environmental impact and bringing about a sustainable society, we continue to develop grades made from cellulose fiber, a biomass material. PLASTRONⓇ RA627P is a new grade that is a composite of PP resin with 30% long cellulose fiber.

Properties of PLASTRONⓇ LFT RA627P

1. Physical properties

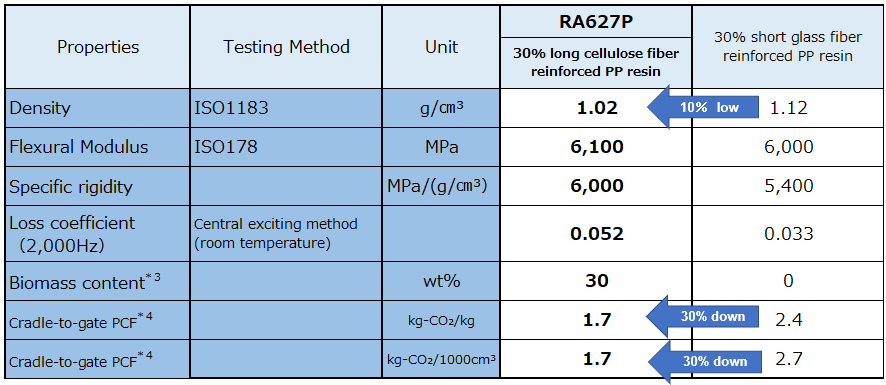

PLASTRONⓇ RA627P is a material that reinforces low-density large-loss-coefficient PP resin with regenerated long cellulose fiber*2 to boost the rigidity of the resin while keeping density from increasing and loss coefficient from declining. The regenerated cellulose fiber used here is manufactured as high strength, high elasticity fiber by choosing the appropriate spinning conditions and degree of polymerization for the raw cellulose materials. As shown in Table 1, PLASTRONⓇ RA627P has the properties of roughly 10% lower density than 30% short glass fiber reinforced PP resin, while maintaining roughly the same flexural modulus. We have also achieved the result of aspecific rigidity that is higher than that of 30% short glass fiber reinforced PP resin, with a large loss coefficient at the same time. The properties of high specific rigidity and large loss coefficient have an inverse relationship, but PLASTRONⓇ RA627P is a material with an excellent balance of those properties, making it perfectly suited for usage applications in components of audio equipment such as speaker diaphragms which require this balance.

*2 Regenerated cellulose fiber: Extracted as continuous fibers by putting natural cellulose through a wet spinning process.

2. Eco-friendly

PLASTRONⓇ RA627P is a long cellulose fiber reinforced PP resin with extremely low product carbon footprint (PCF) made from regenerated cellulose fiber. Its PCF*4 being roughly 30% less (roughly 38% per material volume) than that of 30% short glass fiber reinforced PP resin is another very significant property.

Table 1. Comparison of the physical properties of PLASTRONⓇ LFT RA627P and 30% short glass fiber reinforced PP resin

Our testing methods conform to each of the respective testing standards, but different specifications and procedures are used in some cases.

*3 Value for RA627P natural color variant not containing the color masterbatch

*4 Cradle-to-gate Product Carbon Footprint: Values are calculated from our own results over a set period of time and values in our databases based on the GHG Protocol and ISO 14067 and are not guaranteed values. Includes biogenic carbon removal. (Values current as of November 2024)

Future outlook

We have released PLASTRONⓇ LFT RA627P PP resin reinforced with low PCF cellulose fiber. Due to its properties as a structural material with a large loss coefficient, we consider this material ideally suited for components of audio equipment such as speaker diaphragms and of musical instruments. It is also an excellent choice for the housings and structural components of equipment with rotors or vibrating parts, or of equipment made to vibrate (such as peripheral components for EV motors, housings for head-up displays, various types of fans, and housings for MRI machines). We will make materials propositions for products in various fields with this grade. In addition, we are also developing new grades based on recycled PP resin to further reduce PCF. Moving forward, we aim to expand our portfolio of PLASTRONⓇ LFT products to meet the increasing demands of the market, and accelerate the realization of a circular economy in collaboration with our customers.

For questions or requests regarding this product, please contact our sales representative or inquire through our website.

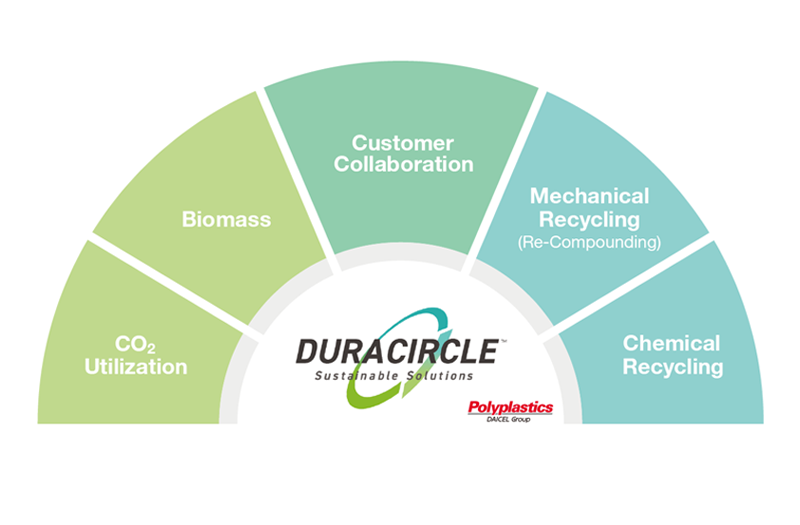

About DURACIRCLEⓇ

As a leading engineering plastics company, we launched our DURACIRCLEⓇ initiatives for every solution that helps to achieve 100% circularity for engineering plastics. Keep looking to Polyplastics for more sustainable solutions.

【Related information】

◆ About PLASTRONⓇ LFT

◆ Special Web Page for Sustainable Solutions under the “DURACIRCLEⓇ” Initiative

【For inquiries about our technologies and materials, please contact us via 】

◆ Polyplastics Group Representative

◆ WEB Inquiry