Our Approach

2024

Development of new DURACONⓇ POM short cellulose fiber reinforced grades: Biomass composite engineering plastics with lighter weight and high rigidity

At Polyplastics, we are advancing R&D on products that reduce environmental impact while maintaining the performance demanded by the market in order to create a recycling-based society. New DURACONⓇ POM short cellulose fiber reinforced grades currently in development are products that meet market needs such as these.

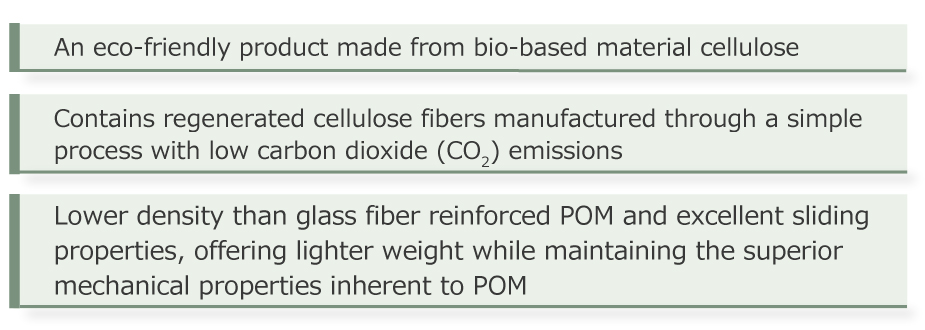

Main characteristics

Uses regenerated cellulose fibers manufactured through a solvent method with low environmental impact

Cellulose is a non-edible bio-based material that contributes to a sustainable society, and it is currently drawing significant attention since it is also known as a carbon-negative material that absorbs carbon dioxide in the atmosphere. In the development of DURACONⓇ POM short cellulose fiber reinforced grades, we use regenerated cellulose*1 manufactured through a solvent method that produces hardly any waste. This manufacturing method with low environmental impact can also reduce carbon dioxide emissions.

*1 Extracted as continuous fibers by putting natural cellulose through a wet spinning process (regenerated cellulose fibers).

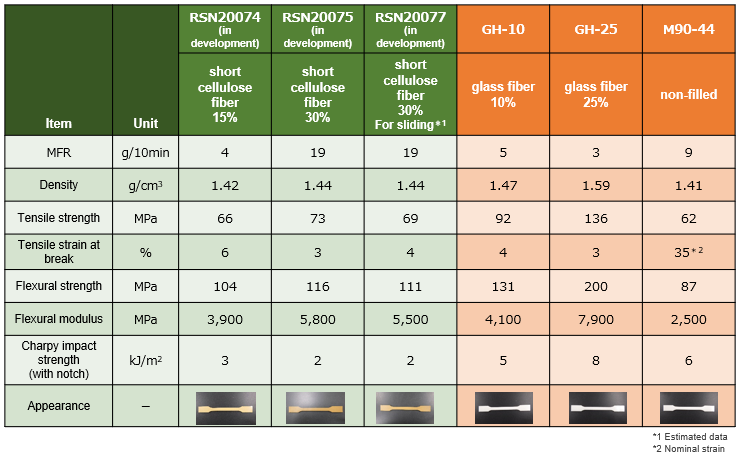

Makes both lighter weight and high rigidity possible

DURACONⓇ POM short cellulose fiber reinforced grades have the characteristics of light weight and high rigidity. Although mechanical properties improve when using glass fibers, which are widely used as resin reinforcing material, the high specific gravity of glass causes a significant rise in the density of the composite. Conversely, flexural modulus can be increased without significant increases in density when using cellulose fiber as resin reinforcing material.

Table 1: General physical properties of DURACONⓇ POM short cellulose fiber reinforced grades

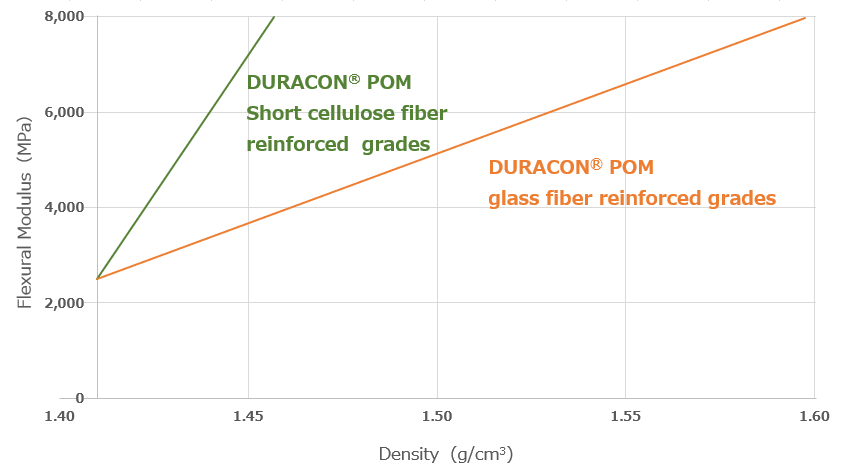

Figure 1: Comparison between DURACONⓇ POM short cellulose fiber reinforced grades

and DURACONⓇ POM glass fiber reinforced grades

(flexural modulus by density)

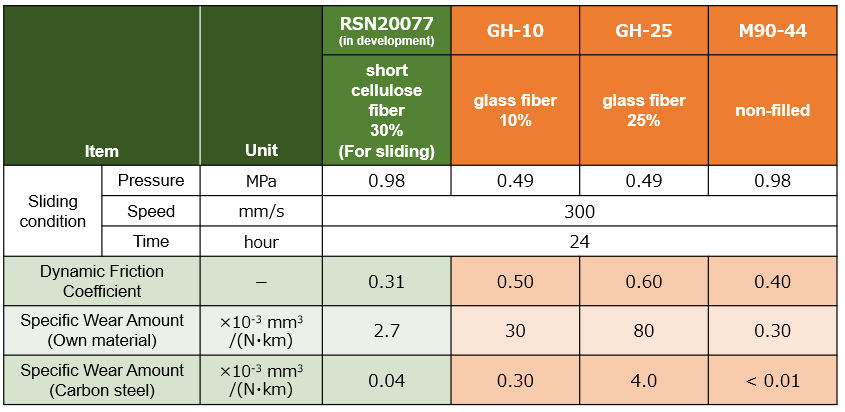

Maintains the superior sliding properties inherent to POM

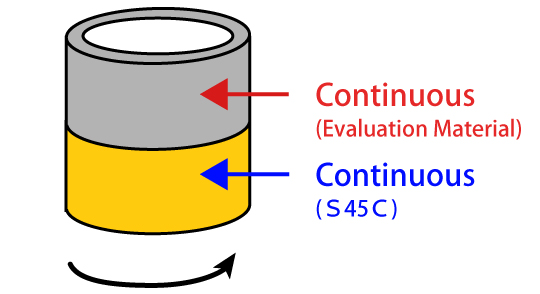

Superior sliding properties are a characteristic of POM. However, when reinforcing POM with glass fibers, the glass fibers tend to cause wear in the other material when sliding. This makes it difficult to have strong mechanical properties at the same time as good sliding properties. But with DURACONⓇ POM short cellulose fiber reinforced grades, the cellulose fibers cause little wear in the other materials (carbon steel, S45C). This makes it possible to have high rigidity along with superior sliding properties.

Table 2: Sliding properties of DURACONⓇ POM short cellulose fiber reinforced grades

Figure 2. Schematic diagram of sliding state (Suzuki method)

Future outlook

In developing DURACONⓇ POM short cellulose fiber reinforced grades, we are seeking to further reduce environmental impact through the application of DURACONⓇ bG-POM*2 and usage of PCR*3 materials collected from the market. We will also be working on the material design to find a way to achieve the high strength that was not possible with conventional short cellulose fiber reinforced grades.

*2 ISCC Plus-certified (International Sustainability & Carbon Certification) mass balance approach biomass allocated POM which we manufacture and sell.

*3 Post-consumer recycled. Refers to collecting used products from the market and recycling them

Sample availability

DURACONⓇ POM short cellulose fiber reinforced grades are under development, but samples are available. Customers can check the properties of these products on their own and explore the possibilities. For details, please contact the Polyplastics sales office in your area or visit our website.

About DURACIRCLEⓇ

As a leading engineering plastics company, we have introduced the DURACIRCLEⓇ initiative. This aims to achieve a 100% circulation of engineering plastics. We will continue to expand our lineup of environmentally friendly products and strive to create sustainable products for our customers.

【Related information】

◆ Special Web Page for Sustainable Solutions under the “DURACIRCLEⓇ” Initiative

◆ Start of DURACONⓇ bG-POM Production Utilizing Biomass

◆ Development of Sustainable Technology

【For inquiries about our technologies and materials, please contact us via 】

◆ Polyplastics Group Representative

◆ WEB Inquiry