Our Approach

2024

Biomass Balance LCP Reduces CO2 Emissions and Improves the Ratio of Renewable Content

Polyplastics is set to unveil LAPEROSⓇ bG-LCP*1, which will replace the raw materials in liquid crystal polymer (LCP) with biomass-derived alternatives using a mass balance approach. This product is the second entry in the bG Series of biomass balance products, and it is planned for release in spring 2025. The manufacturing process, chemical, and physical properties of this new LCP are identical to those of conventional products. Polyplastics plans to expand this new product to include all grades of LAPEROSⓇ LCP offered.

*1 The reduction rate of CO2 emissions and the ratio of renewable content vary by grade. Our target ratios for renewable content are available in our downloadable materials.

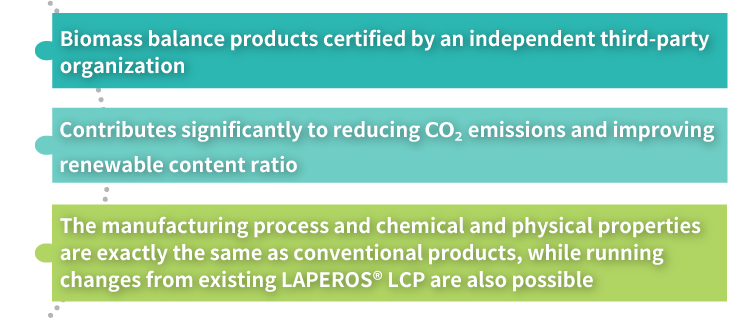

Main characteristics of LAPEROSⓇ bG-LCP

LAPEROSⓇ LCP is an outstanding “super” engineering plastic with thin wall and high flowability characteristics that go beyond the conventional norms of engineering plastics. It has exceptional heat resistance and remarkable mechanical strength, and its strength per unit area increases as it becomes thinner. Additionally, it has a low linear expansion coefficient similar to that of metal. LAPEROSⓇ LCP is used in many ultra-small precision connectors and other components of cutting-edge IT devices such as tablets and smartphones. As a leading company in LCP, we are dedicated to product development and providing technical and customer support.

What is the mass balance approach?

The mass balance approach is a methodology that involves combining raw materials derived from both biomass and fossil resources, and inputting them together into resin manufacturing processes. A portion of the resulting product is considered to be biomass-derived based on the volume of biomass raw material input. From the perspective of resin manufacturers, this eliminates the need to produce biomass-derived and fossil resource-derived products separately. Users also do not have to re-evaluate performance and quality for each separate grade. As a result, this approach can effectively help in achieving a carbon-neutral society and a circular economy more quickly.

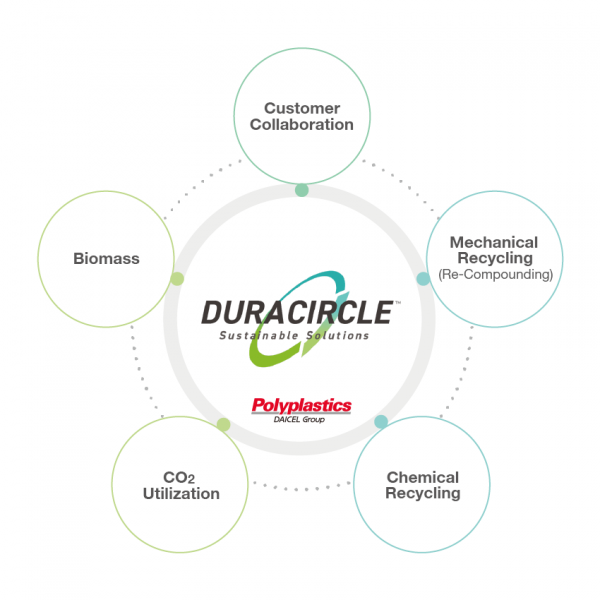

About DURACIRCLEⓇ

As a leading engineering plastics company, we have introduced the DURACIRCLEⓇ initiative. This aims to achieve a 100% circulation of engineering plastics. We will continue to expand our lineup of environmentally friendly products and strive to create sustainable products for our customers.

First entry in the bG Series: DURACONⓇ bG-POM

See the page below for details about DURACONⓇ bG-POM, the first entry in the bG Series and one of our DURACIRCLEⓇ initiatives.

◆ Sustainability website: Production launch for DURACONⓇ bG-POM which uses biomass

【Related information】

◆ Our “SUSTAINABILITY”: Engineering Plastics Business -Development of Sustainable Products-

【For inquiries about our technologies and materials, please contact us via 】

◆ Polyplastics Group Representative

◆ WEB Inquiry