Our Approach

2023

Thermal Management of Electric Vehicles (BEVs): Why POM and Long Fiber Reinforced PP are the New Choice

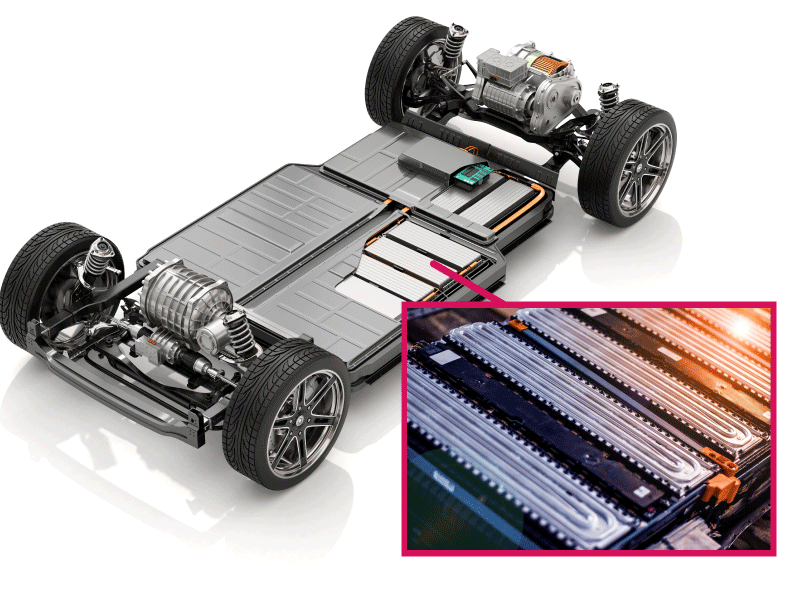

The transition from traditional combustion engine vehicles to battery electric vehicles (BEVs) is rapidly gaining momentum due to growing concerns about global environmental issues. The effective management of heat in BEVs, or thermal management*1 , plays a crucial role in determining their driving range, electricity costs, as well as the overall performance and durability of the lithium-ion battery (Li-ion battery or LIB). Therefore, carefully considering the materials used for thermal management components in BEVs is of the utmost importance to ensuring optimal results.

*1 Thermal management: monitoring and managing the temperature of each system in the vehicle so that it can be maintained at an optimal temperature. Each system is controlled and cooled by fans, coolants (water and oil), refrigerants, etc.

Changes in thermal management systems in BEVs

Efficient use of heat is crucial for battery electric vehicles (BEVs), and one way to achieve this is through an integrated thermal management system that covers the entire vehicle. This system is designed specifically for BEVs and includes the use of exhaust heat from the motor and air conditioning to cooling components.

Automobiles are cooled using a long-life coolant (LLC) that is primarily made of ethylene glycol. The coolant in engines is typically maintained at a temperature of 70-100°C but can rise up to 120°C or higher if the engine overheats. Therefore, metals or high heat-resistant plastics like polyphenylene sulfide (PPS) are used in cooling components and lines.

Battery electric vehicles (BEVs) do not have engines as heat sources and therefore require an LLC temperature of 100°C or lower. This allows for the use of less heat-resistant materials for BEV-specific components.

Plastic Classification and Heat Resistance

Suggesting materials for the cooling components in BEVs

When the temperature of a long-life coolant LLC is 100°C or lower, general-purpose engineering plastics like polyoxymethylene (POM) can be used instead of metals or super engineering plastics. In the case of polypropylene (PP), we recommend using PP-LGF (LGF: long-glass fiber) in place of short glass fibers to increase strength, dimensional accuracy, and overall performance. Replacing high heat-resistant plastics such as PPS with POM and PP not only reduces material costs but also helps with efforts to reduce CO2 by reducing the carbon footprint of materials and energy consumption during molding.

Plastic characteristics and recommended grades

Assistance with design using CAE is available, along with years of experience and a solid track record

When we replace conventional materials with low thermal resistance materials, durability becomes a concern. At Polyplastics, we have conducted extensive immersion testing on LLCs, gathering data on each plastic type. We offer design assistance using CAE and provide insights based on this data.

Meeting environmental needs

We also offer DURACONⓇ bG-POM*2 made with biomass as an eco-friendly option.

*2 In accordance with ISCC Plus certification, this product uses methanol produced from biomass feedstock. Please refer to our website for details.

https://www.polycsr.com/en/highlight/2021_01.html

We also have downloadable documents detailing the durability of each plastic. For inquiries or requests, please contact one of our sales representatives or click “Contact Us” at the top right of this page.

【 Related information 】

◆ Bump-off Molding with DURAFIDEⓇ PPS

◆ CAE Technologies of Polyplastics

◆ New PLASTRONⓇ LFT: An eco-friendly long cellulose fiber reinforced resin, aiding in reducing GHG emissions

[ For inquiries about our technologies and materials, please contact us via ]

◆ Polyplastics Group Representative

◆ WEB Inquiry