Our Approach

2024

DURANEXⓇ rG-PBT Utilizes Raw Materials from Mechanical Recycling

Polybutylene terephthalate (PBT) is widely used in auto parts, electrical/electronic components, and various types of precision components due to its high heat resistance and superior electrical properties. Requirements to cut down on environmental impact have increased in recent years for products in these fields. To address these market needs, Polyplastics has developed new DURANEXⓇ rG-PBT GHB336, which uses mechanically recycled raw materials.

Containing 30% PCR-PET, this material helps reduce PCF and improve recycled raw material usage rates

DURANEX® rG-PBT GHB336 is a glass fiber 30% reinforced grade containing 30% recycled PET raw materials. Recycled PET raw materials use mechanically recycled materials from the market (PCR materials*1) and help to reduce PCF*2*3 and improve recycled raw material usage rates.

*1 PCR: Post-Consumer Recycled

*2 PCF: Product Carbon Footprint

*3 Switching to GHB336 from a standard glass fiber 30% reinforced PBT grade is estimated to have the effect of reducing PCF value by approximately 1/4

We support customers’ product development with the same level of quality control and technical services as for existing products

Since DURANEXⓇ rG-PBT GHB336 has properties close to those of DURANEXⓇ PBT 3300 (standard PBT-GF30) and 3306 (standard PBT/PET-GF30), it makes a suitable replacement for standard glass fiber 30% reinforced PBT grades.

Table 1. Comparing typical physical properties figures of new product DURANEXⓇ rG-PBT and DURANEXⓇ PBT

We also have downloadable documents with details on specific physical properties and moldability.

DURANEXⓇ rG-PBT GHB336 is also produced under the same level of quality control as DURANEXⓇ PBT, with the same technical services as provided for existing grades. This exemplifies how we are helping our customers advance their product development with a sense of reassurance.

Future outlook

We are currently working on developing DURANEXⓇ rG-PBT grades with superior hydrolysis resistance and have begun offering samples. Going forward, we will continue offering engineering plastics solutions with the aim of reducing our environmental impact and contributing to a recycling-based society.

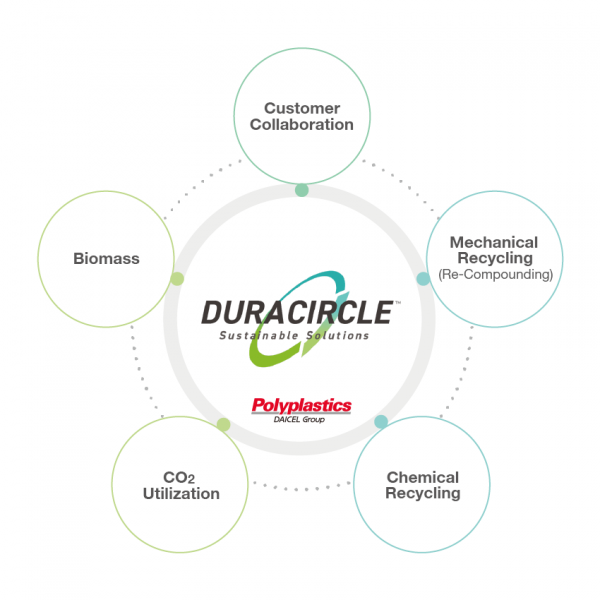

About DURACIRCLEⓇ

As a leading engineering plastics company, we have introduced the DURACIRCLEⓇ initiative. This aims to achieve a 100% circulation of engineering plastics. We will continue to expand our lineup of environmentally friendly products and strive to create sustainable products for our customers.

【Related information】

◆ Material Properties Information:DURANEXⓇ rG-PBT GHB336

【For inquiries about our technologies and materials, please contact us via 】

◆ Polyplastics Group Representative

◆ WEB Inquiry